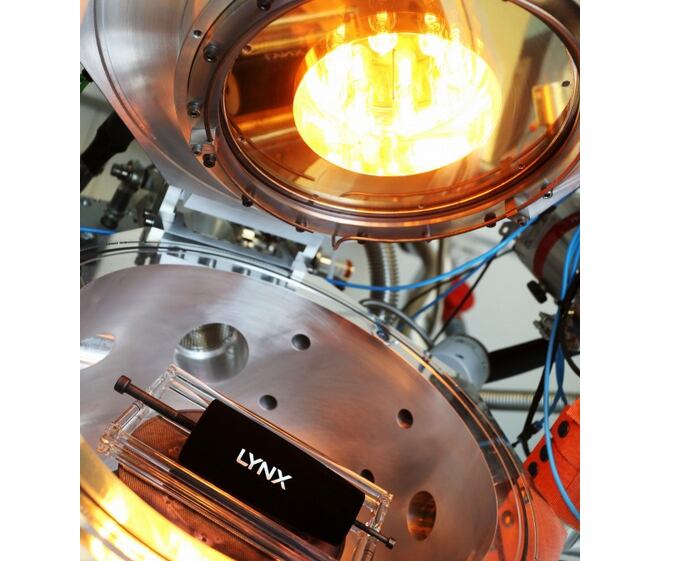

Surrey NanoSystems applied the low-temperature carbon nanotube material to a black Lynx can over a period of 400 hours which is 10,000 times thinner than a human hair.

For a limited time only, the first consumer product to be manufactured with the material, is being showcased at the 'Lynx Black Space on Dray Walk' in a London gallery.

Manufacturing 'super-black' carbon nanotube-based materials has traditionally required high temperatures, preventing their direct application to sensitive electronics or materials with relatively low melting points.

"This is the most innovative project we have ever worked on. The material was an obvious fit for our new product range, Lynx Black, understated and slick, whilst pushing the barriers of science and technology and giving people a truly unique opportunity to view it," says David Titman, Lynx marketing manager.

A new method for manufacturing carbon nanotube-based materials

Manufacturing 'super-black' carbon nanotube-based materials has traditionally required high temperatures, preventing their direct application to sensitive electronics or materials with relatively low melting points.

This, along with poor adhesion, prevented their application to critical space and air-borne instrumentation.

However, after a two year development programme, Surrey NanoSystems discovered how to transfer its low-temperature manufacturing process from silicon to aluminium structures and pyroelectric sensors.

According to a company spokesperson;"Vantablack has the highest thermal conductivity and lowest mass-volume of any material that can be used in high-emissivity applications. It has virtually undetectable levels of outgassing and particle fallout, thus eliminating a key source of contamination in sensitive imaging systems."

"It withstands launch shock, staging and long-term vibration, and is suitable for coating internal components, such as apertures, baffles, cold shields and Micro Electro Mechanical Systems (MEMS) –type optical sensors," they add.

As a spin-off from its work in applying nanomaterials to semiconductor device fabrication, Surrey NanoSystems’ manufacturing process also enables Vantablack to be applied to flat and three-dimensional structures in precise patterns with sub-micron resolution.